Equipment List

Laser

- (1) Amada LCG 3015 2500 Kw Fiber Laser with Load Cell/ W EZ cut nitrogen generator

- (2) Mitsubishi ML3015EX 4500 Kw CO2 laser with 12 Shelf Load Cell 60″x120″

- (2) Mitsubishi 3015EX F40 Plus 4000Kw Fiber Optic with 12 Shelf Load Cell

- (2) Mitsubishi 6000kw fiber optic with load shelf capability

Forming

- (1) Mitsubishi bh 8525 press brake with videre system

- (1) Mitsubishi bh 1353 press brake

- (4) Amada RG 100. 100T with 10′ bed

- (1) Amada Promecam press brake

- (4) Amada RG50 W 9ex control. 50T with 60″ bed

- (4) Amada RG 80 8′ bed

- (1) Amada Fab80. 80T X 8′ bed

- (1) Baykal 175T x 12′ bed

- (1) Amada RG35. 35T with 4′ bed

- (1) 6′ FAB50

- (1) 10′ FBD AUTOCAM

- (1) 13′ Amada RG 100L. 100T W13′ bed

- (1) Amada Astro Bending Robot

- (2) Amada HFE M2 1303 10′ bed

- (2) Amada RG 125 10′ bed

- (2) Amada RG M2 804 8′ bed

- (1) HFE M2 1303 Pressbrake

- (1) Amada RG-50S pressbrake with NC9-EX control

- (5) Amada RG-50 pressbrake with NC9-EX control

- (7) Amada RG-100 pressbrake with NC9-EXII control

- (1) Amada FBD-1025 pressbrake with NC9-F

- (2) Amada FAB-50 pressbrake with NC9-EXII control

- (1) Amada FAB-80 pressbrake with NC9-EXII control

- (1) Amada FAB-200 pressbrake with NC9-EX

- (1) Diacro 30 ton hydraulic pressbrake

- (1) Amada Astro 100 FaBIII-8025 Bending robot

- (3) Amada RG-80 pressbrake with NC 9 EX II control

- (2) Amada RG-80 pressbrake with NT controls

- (2) Amada RG-125 pressbrake withNC 9 EX II control

- (2) Amada RG-100 pressbrake with NC9-EXII control

- (1) Amada Promacam pressbrake with OP-X control

- (1) Cincinnati mechanical pressbrake with DRC 30″ NC

controlled backgage - (1) Milton Equipment Co. Rolls. – 16 ga x 48″ Initial Pinch Powered

- (1) Famar, Italian Rolls Model #: A314-204 9 ga x 72”

Initial Pinch Powered - (1) Roundo 6′ x 10 ga bend roll

- (1) Baykal Compact Series APHS 3104 x 90

- (1) Amada HS 1303 press brake

- (1) Amada RG80M2 press brake

- (1) Amada FBD press brake

- (1) Amada HFEM2 press brake

- (1) 110 ton Danly Punch Press

- (1) 250 ton Niagara Punch Press

- (1) 300 ton Aida Punch Press

- (1) 200 ton Flexopress Punch Press

Turrets

- (1) Amada NCT 3510 Turret Punch press with Load Cell

- (1) Amada Vipros 355 Turret punch press W Load cell

- (1) Amada Vipros 355 Turret punch press

- (1) Amada AC255 Electric Turret Punch Press

- (2) Amada EM 2510 Electric Turret Punch Press 22 ton with Load Cell

- (1) Amada Pega-S Turret Punch Press

- (1) Amada AE255 NT Electric Turret Punch Press

- (1) Amada SPH 30 single punch

- (1) Amada AE2510 NT Electric Turret Punch Press with Load Cell

- (1) Amada Pega 367 Turret punch Press W 60″ wide bed

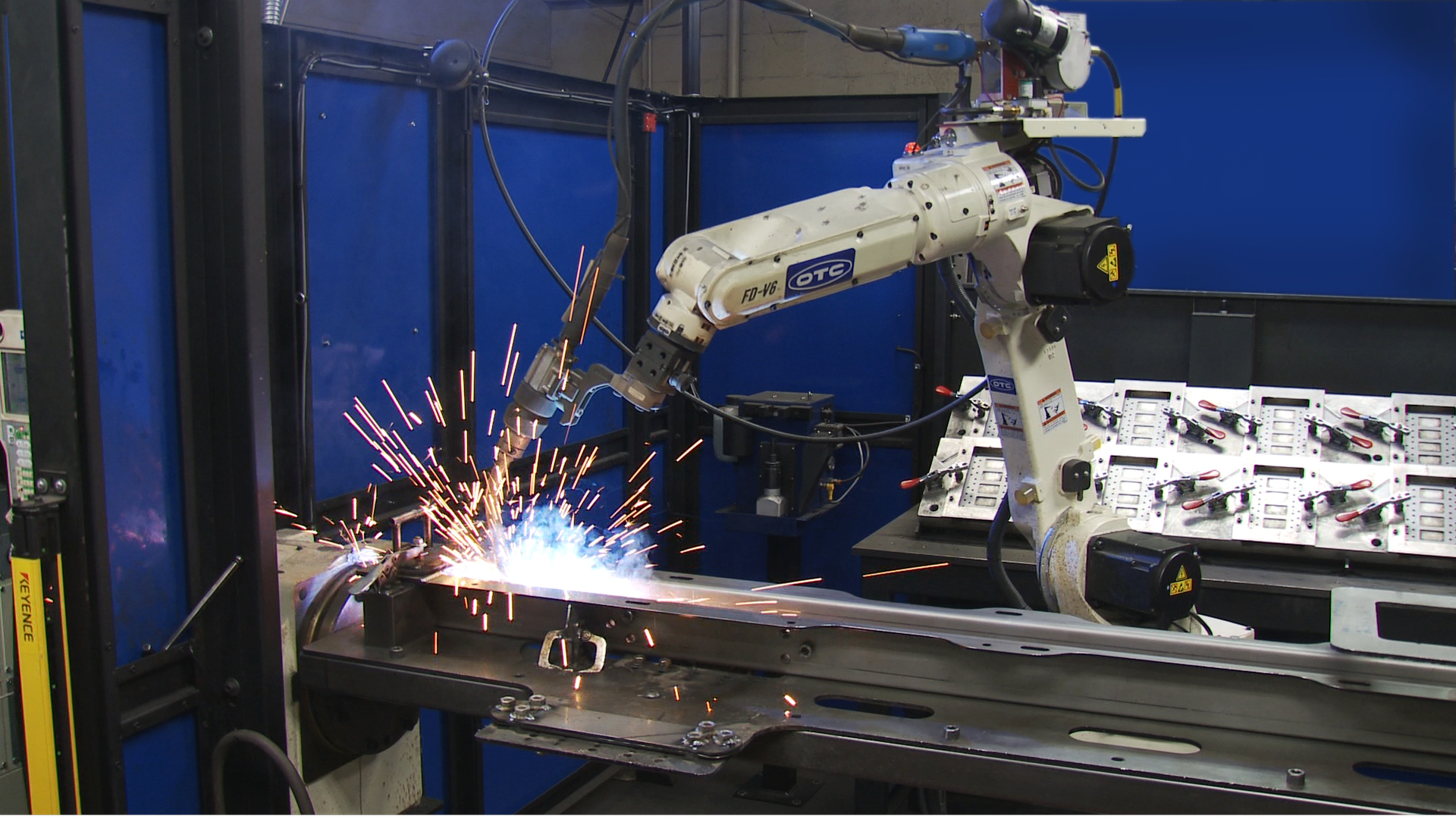

Welding

- (1) TJ snow spot welder

- (1) Amada I1040 IV ST Spot Welder

- (4) otc welbee p400

- (2) otc daihen welbee p500

- (6) robotic welding machines

- (7) miller 350p mig welders

- (2) Sciaky 200 KVIA Spotwelders with chiller and programmable control

- (6) Miller 350P MIG Welders

- (2) Lincoln 225 Square Wave TIG Welder

- (1) Miller 250 MIG Welder

- (2) Miller 251 MIG Welder

- (3) Miller 252 MIG Welder

- (1) Lohrs Suspended 23 KVA Spot Welder

- (1) Lohrs Stationary 75 KVA Spot Welder

- (1) Sciaky 150KVA 3 Phase Spot Welder

- (1) Sciaky 75KVA 3 Phase Spotwelder

- (3) Amada 40ST DC 100 KVA Inverter Controlled Spotwelder

- (3) LTEC 300 AMP TIG

- (2) Miller 300 AMP MIG

- (1) L-Tech 250 AMP MIG

- (2) Panasonic 250 AMP MIG

- (4) Miller 300 AMP TIG: Syncrowave Heliarc Welder W/ Hi Freq. & Chiller

- (3) OTC Daihen DP400 MIG Welder

- (2) Miller Dynasty 350 TIG Welder

- (1) Lincoln 275 Squarewave TIG Welder

- (1) Lincoln 255 Squarewave TIG Welder

Finishing/Assembly

- (1) haeger 824 pem press.

- (1) pemserter series 4 pem press

- (1) haeger 618 pem press

- (5) standard pem press machines

- (2) Conveyorized powder coat systems with 5 stage wash,

- dry off and bake ovens.

- (1) S.S. Electropolishing System

Engineering/Quality

- (2) Amada Fabrivision 48×48

- (1) STARRETT Model RCS4040-24 Coordinate Measuring Machine

- (6) 36″ x 48″ granite surface plates

- (2) Glossmeter for paint

- (2) electronic coating thickness testers

- Misc Digital height gauges to 40″

- Misc Digital calipers to 40″

- Set of precision squares

- (1) set of outside micrometers 1″ to 12″

- Misc. radius gauges

- Angle plates and parallels (various sizes)

- Misc Precision levels

- Misc Precision bevel protractors

- Misc Precision straight edges (various sizes)

- Set of depth gauges

- Gage block set

- Pin gauge sets

- Misc. dial indicators

- Pro engineer software

- AP 100 software

- Sheet works software

- Autocad software

- NCELL software